As a user, you are at the center in the center of the action.

DOPPKON.

For B2B & Sales.

You would like to implement or outsource a development project? Are you looking for a partner for the manufacture of complete surgical instruments? You need a contract manufacturer in the fields of turning, milling, surface machining or laser welding? You would like to expand your product portfolio with surgical instruments from our range? Then you have come to the right place!

DOPPKON – We love medical technology.

Let us create something new together.

We are convinced that the success of a company is based on the people who dedicate part of their lives to it every day. Those thinkers and doers who create something unique together through their ideas, differences, experiences, values and their humanity. We are driven by a high standard of “WHAT” we do for you. We check feasibility and market potential in the possible area before we initiate the “HOW”. To ensure that the result makes your company more successful and drives the medicine, we prefer to think twice. We can draw on experience from numerous projects in the field of medical technology. But as different as our customers and their products are, as different are our performance results. Please understand that due to confidentiality obligations we cannot provide references. Instead, you will find an overview of our range of services, our experience in medical indications and our product portfolio.

What we offer

Contract & subcontract manufacturing

With our modern equipped production we act as an extended workbench or offer you individual machining processes as a contract manufacturer, such as:

Development services

We support you in new or further developments of a product or complete system with complete development documentation or take over individual tasks such as:

Manufacturer & OEM/PLM

We deliver our existing product portfolio with or without technical documentation for the disciplines:

DOPPKON. Your partner.

Our development services

Wide range of services

Our range of services includes the development and design of products as well as the project planning of complete systems in various areas of medical technology. We aim to be able to support you exactly where you are stuck. This can already happen at the very beginning: You have an idea and don’t know where to go with it, how to implement it, what market potential it has or whether it is even feasible. Or your development department has no capacity for another development project. Outsource it and get an external view on the matter. That’s exactly what we are here for.

Broader perspective

We have learned to look at things from a 360° angle and often find unique solutions as a result. Maybe you have even already developed something and would like to finally get your hands on your idea. We can help you with this as well: Prototype, functional sample and series production run within our own four walls and are supported by our large network of suppliers and service providers. As required in development – under the strictest conditions of secrecy.

How it all begins…

Conception

We accompany the entire development process, from conception and design to the creation of production drawings and documentation. First of all, we work out a concept together with you: form, material, functionality – this is about the basic requirements for the new product.

Development according to standard.

Development

In close cooperation with our customers we develop and optimize standard and special instruments. You can use our knowledge and experience for complete development projects as well as for individual project phases. Of course, we document the development process according to the requirements of ISO 13485 and the Medical Device Regulation (MDR).

And this is how it works

The development process

Definition phase

Also referred to as the concept phase, this stage of development involves conceiving ideas and testing their feasibility. This also includes feasibility studies as well as market research and the definition of product requirements.

Prototype stage

In this stage the actual construction of the product takes place. With the help of simulation techniques, functions can be analyzed in order to initiate the construction of a prototype or even a functional sample in the following step.

Qualification phase

In the qualification phase, the functionality and quality of the individual assemblies and parts are validated in order to subsequently be able to define individual process steps for production and to ensure economic efficiency.

Industrialization

Now that feasibility has been ensured, minor adjustments to material procurement and production technology can be implemented so that series production can follow after the pilot series.

Elaboration in detail up to the workshop-ready drawing.

Construction & Detailing

CAD designs are part of the product development process, but can also be used individually – from the design of individual components to the realization of complex assemblies. The elaboration is done in detail up to the workshop-ready drawing, so that production and test drawings are created directly from the CAD models. We use Solid Works as our 3D CAD system.

Explore physical possibilities.

FEM calculations

FEM calculations can be used to identify and analyze not only weak points but also possible material savings as early as the concept phase. Especially in medical technology, it is important to perform numerous calculations, simulations and analyses on the critical areas in the case of thin, filigree instruments. FEM simulation is part of the overall development process, but can also be used as an independent and dependent service.

Holding the idea in your hand.

Rapid Prototyping

See and feel a product or part before it goes into mass production. For this purpose, the production of prototypes takes place at our company with the help of modern techniques such as:

In this way, numerous materials such as metal, ceramics or plastics can be manufactured into functional and resilient prototypes or even biocompatible functional models.

Everything from a single source.

Series production

You need a competent partner for your series? We are happy to help you. As a successful conclusion of a development process, we will gladly manufacture products for you as an extended workbench or as a contract or subcontract manufacturer of individual parts. For this purpose, we have the following in-house manufacturing and processing facilities:

Our disciplines

Ophthalmology

Ophthalmology

Neurosurgery

Brain surgery

Gynecology

Gynecology

Orthopedics

Osteotomy

Pneumology

Lung surgery

Nephroscopy

Nephroscopy

Cardiology

Cardiac surgery

Gastroenterology

Internal medicine

Our disciplines

Since the beginning of our company we have not only developed and manufactured on behalf of our customers, but also realized our own product portfolio of surgical instruments.

01

Spine surgery

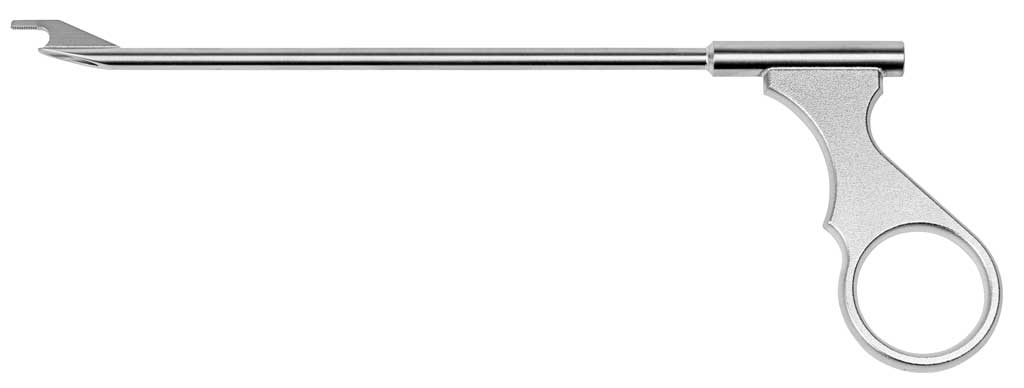

For spine surgery we offer a comprehensive portfolio of grasping forceps with different working ends, lengths and diameters, drills, trephines, working sleeves and much more.

02

Arthroscopy

We have instruments for knee and shoulder surgery such as aiming device, suture passer, drill and complementary products for arthroscopy.

03

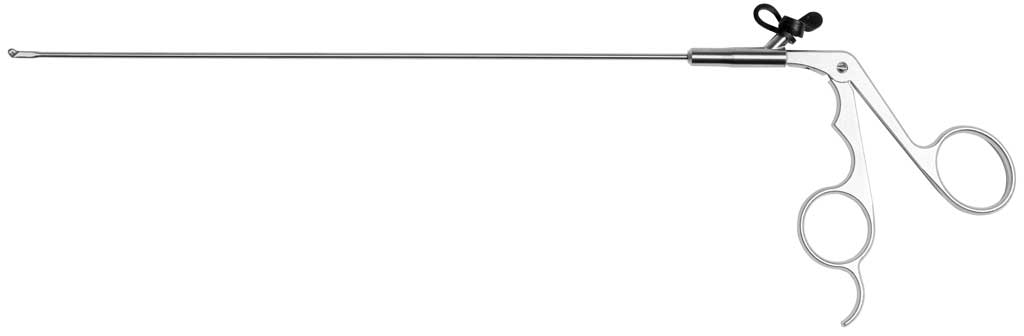

Endoscopy

Laparoscopic instruments for various surgical procedures complete our product range. These include surgical instruments for hysteroscopy, nephroscopy, urology and many more.

Feel free to send us a request!

Do you have an idea?

We listen to you.

“We are your partner for development projects in medical technology!”

Your contact person

Alexander Doppelstein

Founder and Managing Director Alexander Doppelstein and his competent team are at your disposal.